Achieving precise measurements in intense environments presents a substantial challenge for researchers and engineers. Changing pressures can affect the readings of traditional measurement instruments, leading to inaccurate results. To overcome this issue, specialized instrumentation and techniques are required. These encompass pressure-resistant sensors, robust calibration methods, and sophisticated data acquisition systems.

- Pressure-resistant sensors are designed to withstand the strenuous conditions of high-pressure environments.

- Regular calibration ensures that the instruments remain reliable over time.

- Sophisticated data acquisition systems record pressure readings with remarkable precision.

By employing these strategies, scientists and engineers can obtain reliable measurements in high-pressure environments, enabling vital advancements in fields such as materials science, petroleum engineering, and more info geophysics.

Advanced Ultrasonic Flow Measurement in Pressurized Systems

In demanding industrial settings, where pressures are exceptionally high, standard flow metering solutions often fall short. Ultrasonic flow metering emerges as a robust alternative, enabling accurate and dependable measurement in these challenging environments. The concept behind ultrasonic flow meters relies on the transmission of high-frequency sound waves through the flowing fluid. By analyzing the interval taken for the sound waves to navigate the fluid path, the flow rate can be determined. Ultrasonic sensors are resistant to temperature variations, ensuring consistent and accurate flow measurements even in high-pressure applications.

- Merits of ultrasonic flow metering in high-pressure applications include:

- Reliability: Ultrasonic sensors provide accurate and repeatable flow measurements even under fluctuating pressures.

- Remote Flow Detection: The system does not require any physical contact with the fluid, minimizing process disruption and maintenance requirements.

- Adaptability: Ultrasonic flow meters are suitable for a diverse range of high-pressure fluids, including liquids.

Optimizing Fluid Flow Control Under Extreme Pressure

Fluid flow control under extreme pressure presents considerable challenge in diverse industries. To maintain optimal performance and security within these intense environments, sophisticated control mechanisms are crucial. These mechanisms must precisely regulate fluid movement while withstanding the immense forces at play. Leveraging cutting-edge materials, innovative designs, and refined sensors, engineers are continuously pushing the boundaries of fluid flow control in high-stress conditions.

Identifying High-Pressure Flow Meter

When selecting a high-pressure flow meter for your application, it is essential to consider several factors. The first step is to establish the operating pressure range of the system. High-pressure meters are typically designed to withstand pressures exceeding 1000 psi. , Additionally,, you need to determine the flow rate that needs to be tracked. The meter's accuracy and repeatability should also be evaluated.

- , To illustrate, if you are quantifying the flow of a high-pressure liquid in a chemical process, you would need a meter that is suitable with the chemical composition and temperature.

- Various types of high-pressure flow meters include turbine meters, differential pressure meters, and positive displacement meters. Each type has its own strengths and drawbacks.

- The process of high-pressure flow meter can be , challenging. Consulting with a technical advisor can help you identify the right meter for your application.

Robust Sensor Technology for Demanding Pressure Ranges

In demanding industrial applications where pressure fluctuations are the norm, selecting the optimal/appropriate/right sensor technology is crucial/essential/vital. Conventional sensors often falter to deliver accurate readings in such harsh environments. This is because robust sensor technology/solutions/designs come into play. These sophisticated sensors are engineered/designed/built to withstand a wide range of pressure fluctuations, ensuring reliable and accurate/precise/reliable measurements even in the most demanding situations.

- Attributes such as extreme sensitivity, durability, and temperature/thermal/environmental stability make these sensors perfect for a variety of industrial applications like oil and gas exploration, manufacturing, and utilities.

- Additionally, innovative sensor technologies like capacitive sensors offer greater performance and accuracy in challenging pressure ranges.

Finally, robust sensor technology is essential/critical/indispensable for ensuring efficient operations in industries experiencing demanding pressure ranges. By adopting these advanced sensors, industries can enhance their performance, reduce risks, and reach greater efficiency.

Heavy-Duty Flow Meters Designed for High Pressure

Industrial applications often demand the utilization of flow meters capable of withstanding extreme pressures. These high-pressure flow meters are vital for accurately monitoring fluid volumes in a range of demanding environments, such as oil and gas production, chemical processing, and power generation. Fabricated from sturdy materials like stainless steel or corrosion-resistant alloys, these flow meters are built to ensure accuracy and reliability even under extreme operating conditions.

For meet the rigorous requirements of high-pressure applications, industrial-grade flow meters often incorporate advanced technologies such as ultrasonic or electromagnetic flow measurement. These technologies provide reliable data even in the presence of fluid disturbances.

Furthermore, high-pressure flow meters are often equipped with functions such as remote monitoring, data logging, and alarm systems to enhance process control and safety. These features allow operators to observe fluid flow in real time and take immediate action to potential malfunctions.

Opting for the right high-pressure flow meter is crucial for ensuring accurate measurement, reliable performance, and overall process efficiency.

Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Robbie Rist Then & Now!

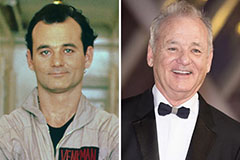

Robbie Rist Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!